Hey Gang!

Sorry I'm just seeing this now. Just trying to stay safe in these trying times. So far, so good for me. I've had a couple of negative tests and stick close to home for the most part

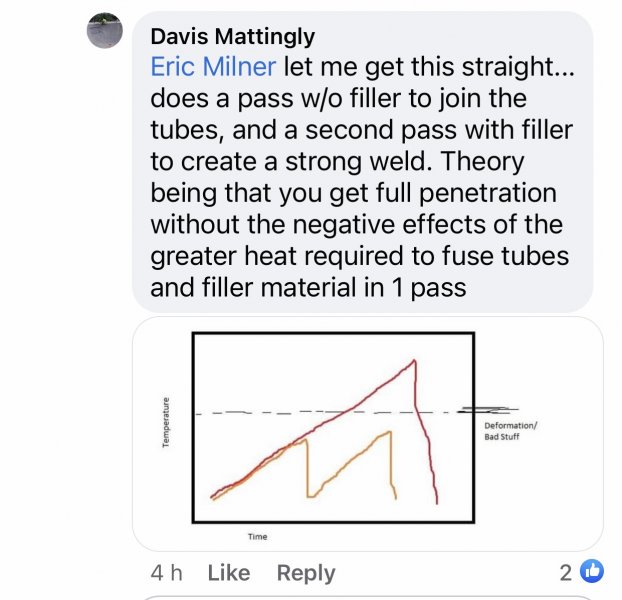

So, to try to answer the question without a PHD dissertation: Titanium welds quite the same as aluminum. You get very shallow penetration for the given width of the weld bead. There are ways to increase the ratio of depth of penetration to bead width but that usually requires using a helium / argon mixture. Helium arcs are much hotter but less stable than straight argon arcs. If you're building tubs for fighter aircraft, sure, use the helium mixture and go like hell. Helium is also quite expensive compared to argon. The current worldwide shortage has driven prices way up.

The benefits to root passing TI joints are just as the gents outlined in the above post. Most of the TI welds on Somerville FAT bikes are two-pass. The notable exceptions are all of the cable guides, the domes on the stays, the seat tube and head tube inserts, the bottle bosses, the cap on the seat stay monotube and the chin gusset.

Another benefit was that we didn't have the sophisticated equipment needed to monitor purge quality and root passing would help to burn out any little bit of O2 left inside the tube before the hotter cover pass was welded. Once the tube joint was sealed, the chance or air leakage into the joint was reduced drastically which lessened the risk of contamination.

When I tested at Seven Cycles in 2019, they also two-pass their TI welds. It's a common acceptable practice.

I do miss welding TI.

Hope everyone is well and cheers to a better 2021

Scott